How do you identify a trustworthy chinese disc harrow supplier?

Table of Contents

When you are looking for a disc harrow manufacturer, it is important to do your research and find a supplier that you can trust. There are many disc harrow manufacturers in China, but not all of them are reliable. How do you identify a trustworthy supplier?

I found that not only do I have this confusion, but many of my friends around me also do not know how to choose the same, so I seriously do research, combined with my years of relevant experience, and friends around the real case, from the following 5 aspects to answer the question.

- Check the company’s website for information about its products and manufacturing process.

- Read customer reviews online to see what others have to say about the company’s products and services.

- If possible, test the supplier’s disc harrows yourself.

- Contact the company directly and ask questions about their products and manufacturing process.

- Compare the prices of different suppliers to ensure you get the best deal.

So how do you find information about products and manufacturing processes on a supplier’s website?

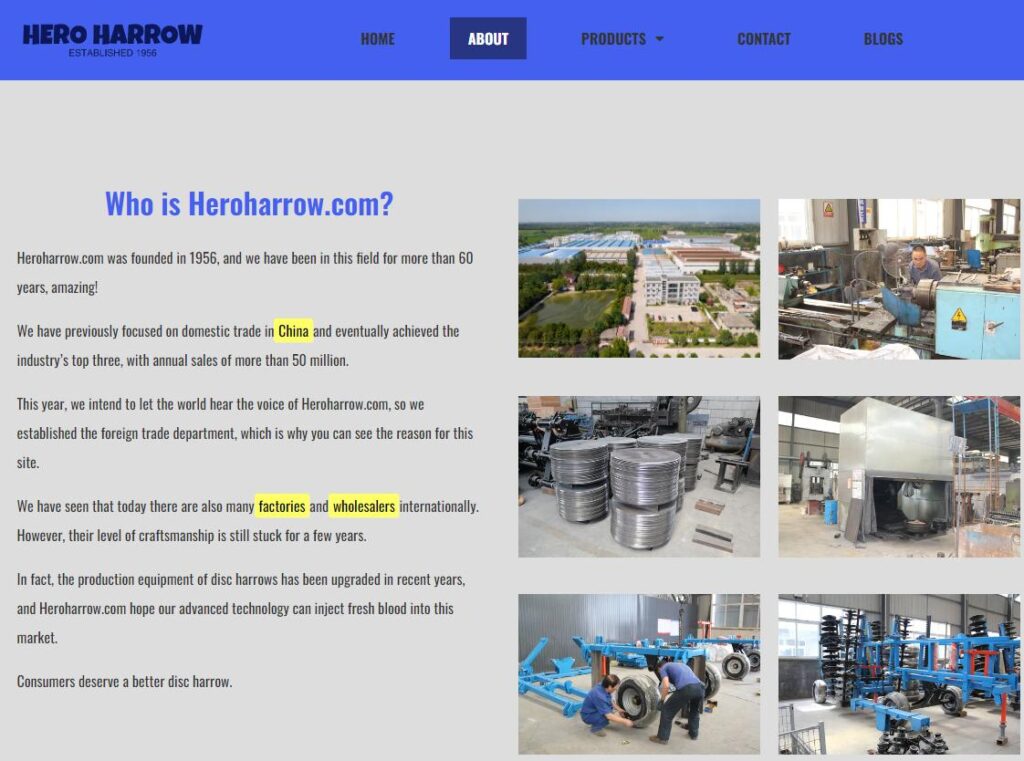

Look for an “About Us” page, which should give you some information about the company. If there is no “About Us” page, or if the information on the page is vague, this is probably not a qualified supplier. So what should a good “About Us” page include?

A good “About Us” page should include.

-The company’s history

-The products they make and how they make them

-Where they export their products to

-Their quality control procedures.

If a supplier has a detailed and informative “About Us” page, this is a good sign that they are likely to be a reliable supplier.

Conversely, the odds are that this supplier is not a qualified supplier.

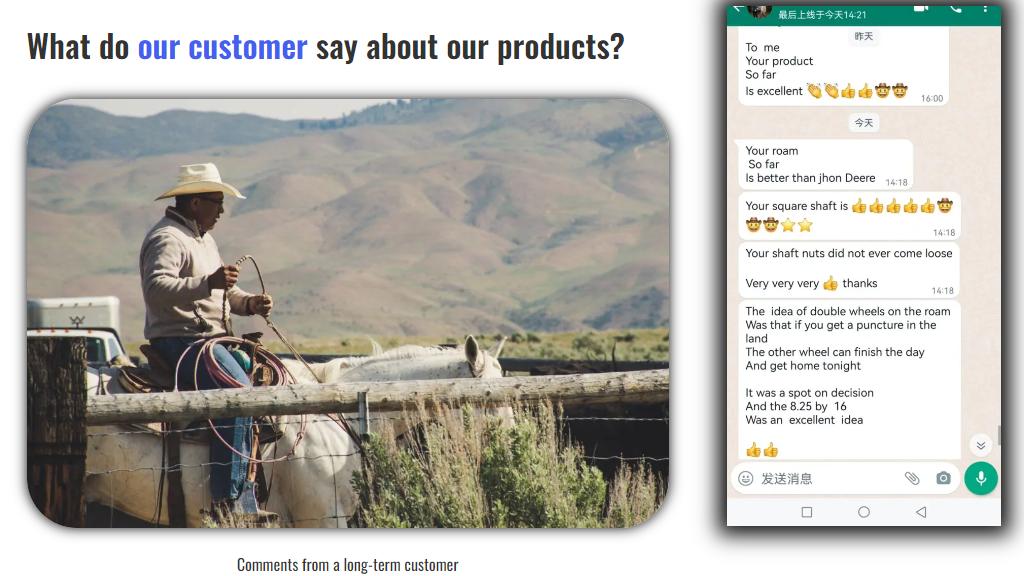

How can you read customer reviews online to see what others are saying about the company’s products and services?

One way is to go to Google and type in the supplier’s name + “reviews”. This will bring up a list of customer reviews. Another way to find customer reviews is to go to the company’s website and see if they have a testimonials page. If they do, this is another good sign that the customer approves of the supplier’s product, otherwise, the supplier would not be able to post negative customer reviews on their website.

Also, you can go to the supplier’s other social media, such as youtube, Instagram, Facebook, etc., to see what the supplier’s customers really say about the supplier.

How can you test the supplier’s products yourself?

If there is a product from this supplier near your area, you can go over there and see the performance of the disc rake in person.

But if you can not see the supplier’s products, you can also ask the supplier to send you a sample to test it.

After the test, you can try buying some products from this supplier.

In addition to quality, another thing you should be concerned about is price.

The price of a product is determined by many factors, such as materials, design, shipping costs, etc.

You should ask the supplier for a quote and compare it with other suppliers.

What are some issues to keep in mind when contacting the company directly with questions about their products and manufacturing process?

The following points must be noted when contacting potential disc harrow manufacturers in China.

-Their level of responsiveness. Do they answer your questions promptly and thoroughly?

-The details they provide in their answers. Are they able to provide specific details about their products and manufacturing process?

-Are they willing to take photos and videos of you in production, or even send you samples of their products?

-Their prices. Be sure to compare prices between different suppliers to get the best deal.

What are some things to keep in mind when comparing prices from different suppliers?

1, Does the quality of the material have a big impact on the price?

When buying any product, price is always an important factor to consider. When looking for a disc harrow manufacturer in China, it is important to compare prices from different suppliers to get the best deal. However, it is also important to remember that the quality of the materials used varies greatly in price.

2, What is the manufacturing process?

The manufacturing process is another important factor to consider when looking for a disc harrow manufacturer in China. It is important to choose a supplier that uses high-quality materials and has a good reputation for manufacturing products.

3, What is the delivery time like?

Delivery time is another important factor, qualified suppliers are able to control the delivery time, while unqualified suppliers, often takes longer to deliver the product.

These are just a few of the factors you should consider when looking for a disc harrow manufacturer in China. By taking the time to compare price, quality, and delivery time, you will be able to find a disc harrow supplier that meets your needs and budget.

In addition, I have a few more points to add so you can have a deeper understanding of disc harrows.

1, the simple history of the disc harrow

The first disc harrow was pulled by a horse or mule. The discs were made of iron and were about 18 inches in diameter. They were mounted on a wooden frame with spokes that allowed them to rotate. The discs cut through the soil and turned it over to make it easier to grow crops.

In the early 1900s disc harrows began to appear in many countries, including China. The first disc harrow in China was made in the 1950s. It was a light machine that could be pulled by animals or tractors.

Today, disc harrows come in many different sizes and models. They are made of steel or iron and can be manual or hydraulic. The disc harrow is used to turn on the soil, break up clods, and level the ground.

Disc harrows are an important part of agricultural equipment. They help farmers prepare their fields for planting and make it easier for crops to grow.

2, Working parts of disc harrows

The working parts of the disc harrow mainly include three parts: the disc blade, Steel Pipe, and the bearings.

The material of the disc blade generally uses wear-resistant 65Mn steel, but also low-carbon martensitic B5 steel. The United States from the 40s, with cross-rolled steel manufacturing disc blades. The center hole of the disc blade piece is generally a square hole, separated by the steel pipe, a disc blade piece with the steel pipe set on the square shaft with a nut lock that becomes the disc harrow group.

The main role of the pipe is to connect and support the disc harrow group. Bearings are usually double-row spherical roller bearings, and can withstand large radial loads and axial loads in all directions.

When working, the disc edge plane is perpendicular to the ground, and the forward direction into a declination. Each rake group is supported by the bearings on the frame. The operation, in the tractor traction and soil reaction force under the action of the rake group of each rake piece with the same square axis whole group rolling. In the rake itself gravity under the action of the rake blade cutting into the soil, cut grass roots or crop stubble, cutting broken after tillage of the fa bar, and make the soil fa along the rake concave surface slightly up, and then turn down, with a certain turn soil and cover role.

3, disc harrow group configuration form

Commonly used disc harrow has the following configuration forms.

1, single-row opposed type

Harrow group on the left and right side of the row into a single horizontal row, the left, and right rows are composed of one or more concave back rake groups. Used for irrigated land leveling, post-harvest stubble removal, and shallow tillage of recreational land.

Double-row opposed type

2, There are two rows in front and back. Each column is symmetrically configured by two rows of harrow groups on the left and right. The concave surface of the discs of the two rake groups in the front row are back to back; the discs of the two rake groups in the back row are between the two discs of the rake groups in the front row and are opposite to their concave surfaces [Figure 4(a)]. In order to avoid the junction of the left and right rake groups of the opposed rake leaves a leaky tillage belt, some opposed rakes will be staggered left and right rake groups [Figure 4 (b)].

Offset type

consists of the front and rear two columns of rake groups with opposite concave surfaces of the disc (Figure 5). As the front and rear columns of the rake group subject to lateral force and traction balance, the operation of the rake width centerline can be farther away from the longitudinal axis of the tractor, so called offset rake. Wide offset rake offset amount can be more than 3 meters. Used in orchards, offset harrow can reach the tractor and can not go in under the canopy operation; because the offset harrow no leakage tillage belt, is also widely used in field operations.

4 disc harrow structure of the whole machine

Disc harrow by the harrow frame, harrow group, traction or suspension device, declination adjustment mechanism and other components. In order to increase the depth of soil, some light, small harrow in the harrow frame is equipped with a counterweight box. 80s production use of the disc harrow, in each piece of disc on the distribution of the weight is larger, there is sufficient capacity to enter the soil, so there is no need to add counterweight and adjust the declination, the harrow set is installed when the declination is fixed in the best position. In the need for shallow plowing, the wheel controlled by the hydraulic cylinder to limit the depth.

The number of rake groups in the front and rear columns of the wide rake, there can be 8 groups, the number of rake blades up to 104. The heavy-duty harrow has a single blade weighing up to 75 kg. The width of the light type rake reaches about 9 meters. The width of the rake more than 4 meters in road transport, the two wings of the rake group can be folded up or the two columns together, horizontal traction.